BIM Leadership

Elzo Construction Company’s internal BIM Leadership Team directs and manages our BIM Working Team. The BIM Leadership Team is comprised of key members from both Elzo, the owner’s representatives, architectural/engineering firms, and subcontractors. Our BIM department works with these firms to ensure the project BIM requirements are understood and delivered by all parties. Bringing experience, integrity, and extensive knowledge of BIM & IPD principles, we work together for optimal results.

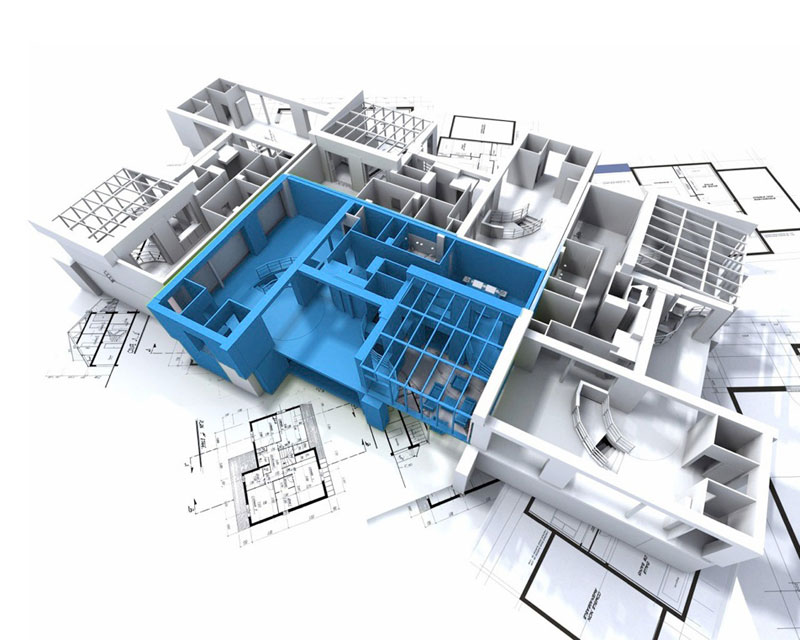

The goals of BIM are to facilitate a collaborative project environment between all team members from project inception to completion and to execute coordinated project documents using the 3D modeling and parametric features of BIM. Using BIM will improve system coordination and the execution of design intent in the field to streamline construction processes. Below are some of the major goals and objectives for our use of BIM.

Key outputs in executing our BIM strategy include the following:

Improved decision-making: Reduce poor design decisions by using digital models and electronic design visualizations during design and construction.

Improved construction documentation: Reduce the level of unknowns in contract documents eliminating/reducing the use of the request for information process to “fill in the gaps.” Leverage BIM to re-establish accuracy and precision, and improve the level of construction cognition and assembly understanding on the part of the architects, engineers, and owners.

Improved preconstruction estimating: Reduce the level of guesswork and inefficiency in preconstruction estimating by leveraging schematic design take-offs generated in the BIM process. Leverage the use of multiple pricing models by the contractor and reuse as-built digital models in new markets.

Improved procurement and scheduling: Reform procurement and project scheduling through the use of time modeling (sometimes known as 4D modeling) and cost modeling techniques—eliminating job-site slow time/downtime and improving sub-trade coordination, overlaps and phasing.

Improved coordination: Reduce the number of field coordination errors by integrating the design models of the major design disciplines early in the design process and using clash detection software to facilitate interdisciplinary design coordination—thereby solving coordination issues virtually rather than in the field.

Improved cost-efficiency: Reduce cost impacts of coordination errors, incorrect fabrication, and improper installation by adopting a pre-fit workflow from the designer to the subcontractor and enforcing greater installation precision. Reduce the use of overtime labor and premium charges for recouping project schedule lost to these unnecessary errors. Reduce spending in general conditions, insurance, and carrying costs by optimizing project schedules that will result in faster construction.

Improved closeout documents: Transform the archaic quality of closeout documents, particularly traditional as-built/record drawings, by migrating to a BIM-centric approach for all project documents. Transition the digital model generated during design and construction to facilities management, allowing the owner/operator to use it for building life cycle management.